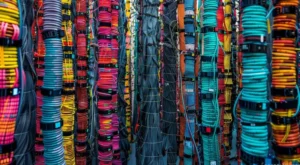

Rubber cables are an essential component in various industries, from manufacturing to construction and electrical installations. They offer excellent flexibility, insulation, and durability, making them ideal for both indoor and outdoor applications. However, not all rubber cables are created equal. To ensure that these cables maintain high levels of safety and durability, suppliers must adhere to strict manufacturing standards and quality control processes. In this article, we will explore how rubber cable suppliers ensure safety and durability, focusing on key factors such as material selection, manufacturing processes, testing, and industry certifications.

Material Selection: The Foundation of Durability

The safety and durability of rubber cable suppliers largely depend on the materials used in their production. Rubber cables typically consist of two primary components: the conductor and the insulation.

Conductors: The conductor is typically made of copper or aluminum, with copper being the most commonly used due to its excellent conductivity. The conductor must be free of defects, such as breaks or fractures, to ensure safe transmission of electricity.

Insulation Material: The insulation of a rubber cable is made from a variety of rubber compounds, often reinforced with other materials such as PVC or thermoplastic elastomers. Suppliers use high-quality rubbers, like EPDM (Ethylene Propylene Diene Monomer), natural rubber, and neoprene, to provide resistance to extreme temperatures, weather conditions, and chemical exposure. The right insulation material ensures that the cable maintains its flexibility, insulating properties, and resistance to wear and tear over time.

Rubber cable suppliers typically select high-grade materials that comply with international standards to guarantee that their cables can withstand the harshest environments, from extreme temperatures to mechanical stress.

Manufacturing Processes: Ensuring Precision and Quality

Once the right materials are selected, the manufacturing process plays a crucial role in ensuring the safety and durability of rubber cables. Suppliers must use precise and well-maintained machinery, along with strict manufacturing procedures to guarantee that each cable meets the necessary standards.

Extrusion of the Rubber Insulation: The rubber insulation is applied to the conductors through an extrusion process. This process ensures that the insulation is evenly distributed around the conductor, preventing weak spots that could lead to electrical failures or safety hazards. Modern extrusion techniques also enable rubber cables to achieve high levels of flexibility, which is critical for use in tight spaces or areas where the cables need to bend or move frequently.

Vulcanization: The vulcanization process is a key part of rubber cable production. This involves heating the rubber to a specific temperature, causing the material to undergo a chemical reaction that makes it stronger, more elastic, and resistant to environmental factors such as moisture, heat, and UV radiation. The vulcanization process ensures that the rubber maintains its physical properties over time, even under extreme conditions.

Stranding and Armoring: For cables that need additional mechanical protection, stranding and armoring techniques are employed. Stranding involves twisting multiple strands of conductor together to provide flexibility and prevent breakage, while armoring involves adding a layer of protective material (such as steel wires) to shield the cable from physical damage. This step is particularly important for cables used in heavy-duty applications, such as construction sites or industrial plants.

Rigorous Testing and Quality Control: Verifying Safety and Performance

Once the rubber cables are manufactured, thorough testing and quality control processes are necessary to verify their safety and performance before they are distributed. Rubber cable suppliers perform several tests to ensure that the cables meet industry standards and customer requirements.

- Electrical Testing: Rubber cables are subjected to electrical testing to verify their insulation properties and ensure that they provide reliable electrical performance. This includes tests for dielectric strength, which measures the ability of the insulation to resist electrical breakdown under high voltage. Cables are also tested for continuity to ensure that the conductor provides a consistent and reliable path for electrical flow.

- Mechanical Testing: Rubber cables are exposed to mechanical stress tests to ensure that they can withstand bending, twisting, and pulling without compromising their structural integrity. The flexibility of the cable is tested by subjecting it to repeated bending cycles, while its tensile strength is tested by applying force until the cable breaks. These tests ensure that the cable can endure the physical demands of its application.

- Environmental Testing: Rubber cables must be able to withstand various environmental factors such as extreme temperatures, UV radiation, moisture, and chemicals. Suppliers test cables for their ability to resist degradation caused by these elements. For example, cables intended for outdoor use are subjected to UV exposure and water immersion tests, while cables used in industrial settings may undergo chemical resistance testing to ensure that the insulation does not break down when exposed to oils, solvents, or other harsh chemicals.

- Fire Resistance Testing: In many industries, fire resistance is a critical safety feature for rubber cables. Suppliers often conduct flame-retardant and fire-resistance tests to verify that their cables can prevent the spread of fire in the event of an electrical fault. These tests include assessing the cable’s performance when exposed to flames, as well as its ability to self-extinguish after the source of ignition is removed.

Industry Certifications and Standards: Compliance with Regulations

To ensure that rubber cables meet safety and performance requirements, suppliers must comply with international standards and certifications. These certifications provide reassurance to customers that the cables are fit for their intended purpose and can be relied upon for safety and durability.

- ISO Standards: The International Organization for Standardization (ISO) provides guidelines for the quality and performance of rubber cables. Many suppliers adhere to ISO 9001 standards for quality management systems, ensuring that their manufacturing processes and products meet consistent levels of quality. ISO 14001 standards for environmental management are also important for suppliers that aim to minimize the environmental impact of their production processes.

- IEC and UL Certifications: The International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) are widely recognized organizations that set safety standards for electrical products. Rubber cable suppliers seek certification from these organizations to demonstrate that their cables meet the necessary safety and performance criteria. For example, UL certification ensures that cables have passed rigorous safety tests and can be used in residential, commercial, and industrial applications.

- RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electrical and electronic products. Suppliers that comply with RoHS regulations ensure that their rubber cables are free from harmful substances like lead, cadmium, and mercury, promoting both safety and environmental responsibility.

The Role of Ongoing Maintenance and Support

While the safety and durability of rubber cables are largely ensured through the manufacturing and certification processes, ongoing maintenance and support are also crucial in prolonging their lifespan and ensuring continued performance. Suppliers often offer guidance on proper cable installation, handling, and maintenance to help customers avoid common issues like physical damage, improper connections, and exposure to harsh environments.

- Installation Recommendations: Proper installation practices, such as avoiding excessive bending or twisting, can prevent damage to the cable’s insulation and conductor. Suppliers may provide installation guidelines to help customers ensure safe and efficient use of rubber cables.

- Maintenance Services: Regular inspections and maintenance of rubber cables can help identify wear and tear, allowing for early detection of potential issues before they lead to failures or safety hazards. Some suppliers offer maintenance services to help businesses maintain the integrity of their cable systems over time.

Conclusion

Rubber cables are crucial for ensuring the safe and reliable transmission of electrical power in a wide range of industries. Rubber cable suppliers play a pivotal role in ensuring the safety, durability, and performance of these cables by selecting high-quality materials, employing advanced manufacturing processes, conducting rigorous testing, and adhering to industry standards and certifications. By prioritizing these factors, suppliers can offer cables that meet the demands of both harsh environments and safety requirements, ensuring that end users can rely on them for long-term performance and safety.

Marian Shields, a dynamic marketing expert, orchestrates brand narratives with finesse and insight. With a keen understanding of consumer behavior and market dynamics, Marian navigates the ever-changing landscape of marketing strategy, crafting compelling campaigns that resonate with audiences worldwide. Through her strategic prowess and creative vision, she helps businesses of all sizes unlock their full potential and achieve tangible results in the competitive marketplace.