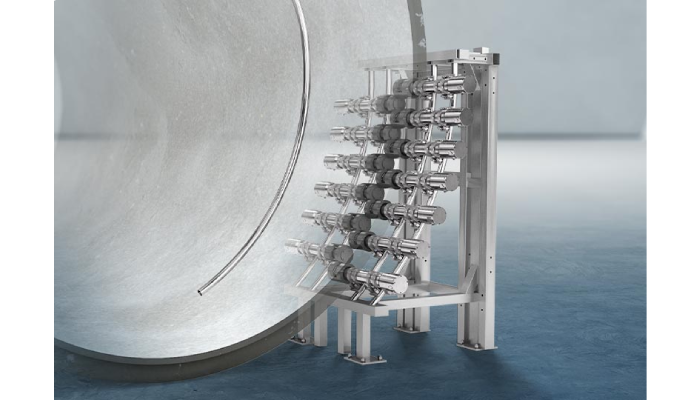

Enzyme-linked immunosorbent assay (ELISA) is a widely used laboratory technique for detecting and quantifying biomolecules, including proteins, peptides, antibodies, and hormones. While ELISA is known for its precision and reliability, manual washing steps in the assay process introduce a significant risk of human error. Inconsistent washing, inadequate removal of unbound reagents, and cross-contamination can lead to inaccurate results. To mitigate these challenges, laboratories rely on ELISA plate washers, which are automated instruments designed to standardize and optimize the washing process. By integrating an ELISA plate washer into your workflow, you can enhance accuracy, reduce variability, and improve overall assay efficiency. This article explores how an ELISA plate washer minimizes human error and ensures consistent, reproducible results in your lab.

The ELISA Washing Process

The washing step in an ELISA procedure is crucial for removing unbound substances that can interfere with the assay’s accuracy. This step typically involves multiple wash cycles using buffer solutions to clear away residual proteins, antibodies, or enzymes. When performed manually, this process requires careful pipetting, aspiration, and dispensing, all of which introduce variability and potential mistakes. Even skilled technicians can experience inconsistencies due to pipetting errors, incomplete washing, or differences in technique. An ELISA plate washer automates this process, ensuring uniform washing across all wells, reducing the risk of contamination, and maintaining the integrity of assay results.

Key Ways An ELISA Plate Washer Reduces Human Error

Eliminates Pipetting Inconsistencies

Manual washing involves repeated pipetting of wash buffer into and out of microplate wells. Variations in pipetting technique, including inconsistent aspiration and dispensing volumes, can impact assay sensitivity. An ELISA plate washer ensures precise and uniform dispensing of wash solutions, eliminating inconsistencies caused by manual handling. This results in more accurate and reproducible assay outcomes.

Reduces Cross-Contamination Risks

In manual washing, improper aspiration of wash buffer can lead to cross-contamination between wells, affecting assay specificity. Droplet carryover from one well to another is a common issue when using multi-channel pipettes or squeeze bottles. ELISA plate washers use automated aspiration systems that effectively remove residual liquid, minimizing cross-contamination and preserving sample integrity.

Ensures Optimal Washing Efficiency

Effective washing requires multiple cycles of buffer addition, incubation, and aspiration. Manually performing these steps can lead to variability in exposure times, impacting assay performance. ELISA plate washers standardize the timing of each wash cycle, ensuring complete removal of unbound reagents while maintaining assay consistency. Automated systems also allow for programmable wash protocols, ensuring optimal conditions for different assays.

Minimizes Operator Fatigue and Variability

Repetitive pipetting and washing can cause operator fatigue, leading to decreased focus and increased error rates over time. This is particularly concerning in high-throughput labs where multiple plates are processed daily. An ELISA plate washer reduces the physical burden on technicians, allowing them to focus on other critical tasks while ensuring uniform washing across all samples.

Improves Standardization and Reproducibility

Reproducibility is essential in scientific research and diagnostic testing. Variations in manual washing can lead to inconsistent results, reducing the reliability of experiments. ELISA plate washers standardize the washing process, ensuring identical conditions for every assay run. This improves reproducibility, making it easier to compare results across different experiments and laboratories.

Prevents Incomplete Washing and Residual Contaminants

Incomplete washing is a major source of assay interference, leading to high background noise and inaccurate measurements. Manual washing often leaves residual reagents in wells, which can contribute to false-positive or false-negative results. ELISA plate washers use optimized aspiration and dispensing mechanisms to ensure complete removal of unbound substances, improving signal-to-noise ratio and assay sensitivity.

Enhances Data Accuracy And Reliability

Inaccurate washing can lead to erroneous absorbance readings, compromising data integrity. Manual washing variability can cause uneven reagent distribution, affecting assay sensitivity. By using an ELISA plate washer, labs can achieve consistent washing performance, leading to more reliable data and accurate quantification of target analytes.

Saves Time And Increases Throughput

Manual ELISA washing is time-consuming, especially in high-throughput labs processing multiple plates. Each washing cycle requires careful execution, increasing the time needed to complete an assay. ELISA plate washers significantly reduce assay processing time by automating washing steps, allowing researchers to handle more samples efficiently without compromising accuracy.

Selecting The Right ELISA Plate Washer For Your Lab

When choosing an ELISA plate washer, it’s essential to consider factors such as compatibility, wash protocols, and automation features. Here are the key aspects to evaluate:

- Plate Compatibility: Ensure the washer supports standard 96-well or 384-well microplates based on your lab’s requirements.

- Wash Programs: Look for customizable wash protocols to accommodate different assay needs.

- Aspiration and Dispensing Precision: Select a system with adjustable aspiration rates to minimize residual liquid.

- Ease of Use: User-friendly interfaces and programmable settings improve workflow efficiency.

- Maintenance Requirements: Consider ease of cleaning and routine maintenance to prevent clogs and system malfunctions.

Conclusion

An ELISA plate washer is a valuable investment for laboratories aiming to minimize human error and improve assay reliability. Automating the washing process eliminates pipetting inconsistencies, reduces cross-contamination risks, and enhances reproducibility. Additionally, it saves time, increases throughput, and ensures optimal washing efficiency, ultimately leading to more accurate and reliable ELISA results. Whether in research, clinical diagnostics, or pharmaceutical testing, integrating an ELISA plate washer into your workflow enhances efficiency and data integrity while reducing the risk of manual errors.

Sharon Bartlett is a Registered Dietitian Nutritionist based in Florida. She is passionate about educating others about the importance of making nutritious food choices and promoting healthy eating behaviors. With a background in clinical, community, and Wellness nutrition, she is adept at addressing the diverse needs of individuals and families. Her expertise in food and nutrition makes her the go-to person to bridge the gap between general wellness and specific dietary concerns. She loves to share her enthusiasm for whole-food nutrition with her blog readers and provide practical tips for everyday living.